Convergence in technology is not a new idea. The concept infers that disparate technologies evolve to a closer association or integration over time. A simple example is a Swiss Army knife (see Figure 1). Who knew someone would need scissors, a bottle opener, and a screwdriver paired with sharp blades?

Fig. 1 The iconic Swiss army knife is a great analogy for integration.

What does this have to do with 224 Gbps PAM4 system design? The same concept applies. Convergence occurs when any number of technologies, such as micro twinax cables, ASIC design, interconnects, advanced IC packaging, and others combine to offer a unique system-level solution. Many see convergence as required for 224 Gbps PAM4 system performance.

Setting the Data Center Table

Bandwidth demand seems to have no end. Newly built 5G networks open new frontiers of global connectivity. Consumer demand for streaming video, social media, AR/VR, and other applications are driving exponential Internet data growth. The recent global coronavirus pandemic has forced millions to work from home. Bandwidth limited networks are being stressed to the limits.

How are data center architects and system designers tackling this insatiable demand for data? They are rolling out servers, switches, and networking equipment that support 56 Gbps PAM4/IEEE 200G system performance. Thankfully, 56 Gbps PAM4 FPGAs, networking ICs, transceivers, and timing solutions continue to ramp. Industry pundits predict full production by early next year. Preliminary 112G PAM4/IEEE 400G systems double bandwidth again, but projected availability is not until 2025.

Optical network connectivity presents opportunities in some network applications. However, there are design concerns here as well. Chassis, rack, and system solutions would need to be completely rearchitected. While copper-based systems leverage existing and amortized infrastructure, in-system optics adoption would require extensive changes and investment in manufacturing infrastructure. Long-term, widespread optical network adoption makes sense, but the 2020s are probably not the decade.

Micro Twinax Cable to the Rescue?

Current PCB-based system architectures offer finite performance and limited trace lengths. Optical-based system architectures are not feasible in the near term. As an alternative, micro twinax cable offers lower loss, long reach, and system flexibility by routing signals over the PCBs instead of through them.

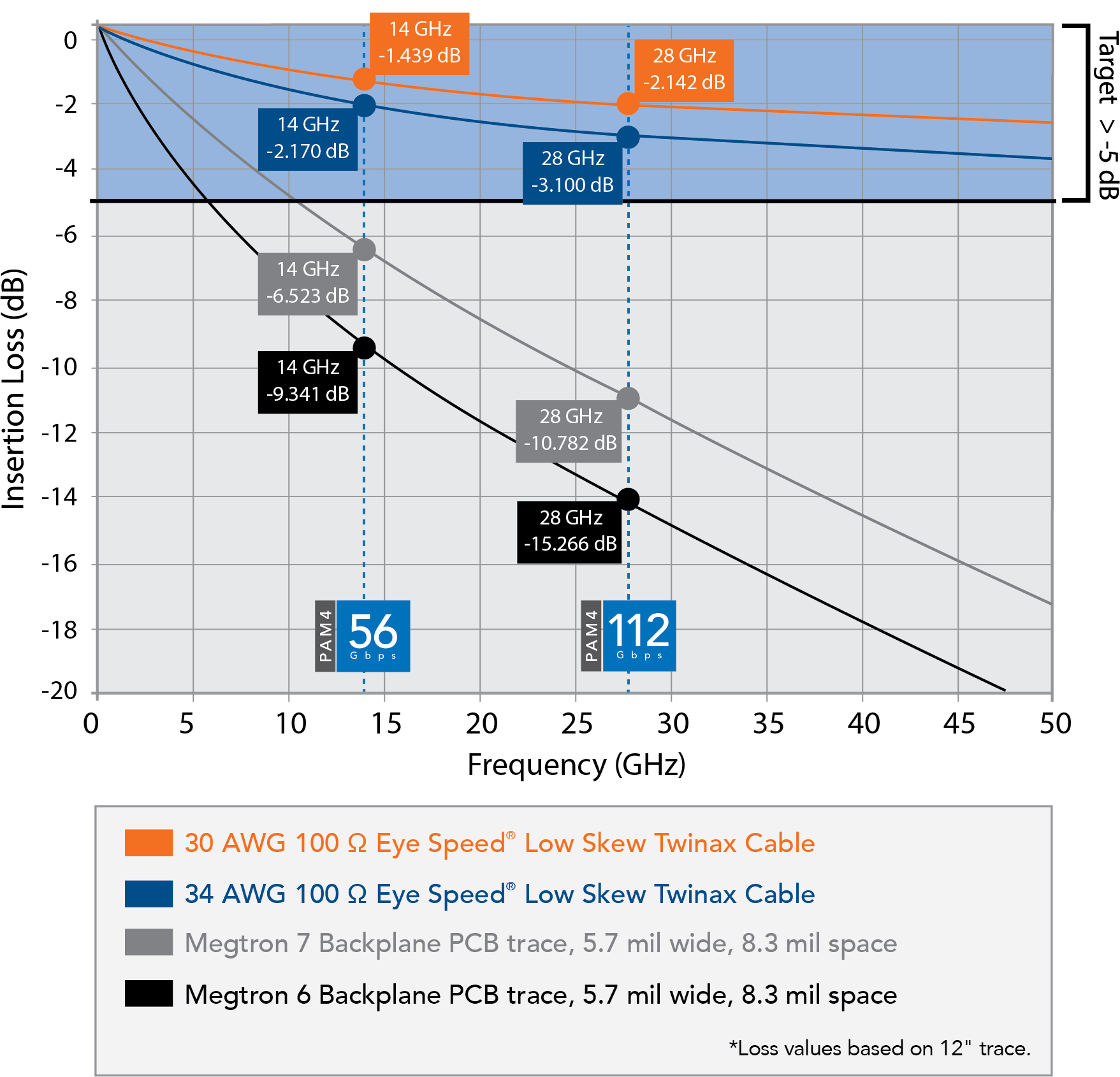

Our team has studied the effects transmission medium has on the insertion loss (IL) of a signal. Figure 2 illustrates the difference of low-skew, micro twinax cables vs. traditional PCB laminate materials. In this case study, low-skew twinax cables improved IL performance vs. MEGTRON6 and MEGTRON7 at a Nyquist frequency of 28 GHz (112 Gbps PAM4/56 Gbps NRZ). The difference at a Nyquist frequency of 56 GHz (off the chart) is even wider, offering a path to 224 Gbps PAM4 system performance.

Fig. 2 Transmission medium effects the insertion loss (IL) of a signal; this graph shows the difference between low-skew, micro twinax cables vs. traditional PCB laminate materials.

In addition to performance, low-skew micro twinax cable also offers system architecture flexibility. The ends of the cable assemblies can be connectorized in any number of ways. This approach offers innovative architectures across the data center. As an example, current pluggable multi-source agreement (MSA) infrastructure uses direct attach cables (DAC) for chassis-to-chassis or rack-to-rack connectivity. However, next-generation MSAs, like QSFP-DD800, recognize the importance of micro twinax cable routing signals from the front panel to the ASIC.

Convergence to 224 Gbps PAM4

Micro twinax cable technology enables 112 Gbps PAM4 data rates. Connectorized micro twinax cable assemblies attach to PCBs alongside system ASICs. Consistent, reliable 224 Gbps PAM4 performance requires removing as much loss from the signal channel as possible. Are there other lossy signal channel components that can be removed?

Current system ASIC designs support 256 Lanes/512 dynamic paths (DP) of 112 Gbps offering 25.6 TB aggregate data throughput while next-gen ASIC designs double that. Routing hundreds of DPs from larger ASIC packages and BGA breakouts cause nightmares for SI engineers and PCB designers. Isolation concerns contribute to the challenge as robust grounding schemes are required. ASIC packaging and BGA breakouts remain a key source of loss in the signal path.

Can micro twinax cable assemblies or fiber optics attach directly to the ASIC substrate? That approach would help eliminate package and breakout-related losses. However, several disparate technologies must evolve and integrate to achieve the desired channel performance.

Attaching micro twinax cable assemblies or fiber optics to the substrate requires a flexible interconnect design. Ideally, enabling copper and optical termination in the same mechanical connection system would simplify design. Reliability features such as connector latches would improve overall ruggedness.

Integrating the connector in the package also presents challenges. High-speed interconnect design and advanced IC package and assembly collaboration is a must. Any solution must also be small enough not to interfere with any thermal mitigation techniques like heatsinks, thermal interface materials (TIM), or liquid cooling.

Like the Swiss Army knife, the convergence of micro twinax cables, ASIC design, interconnects, advanced IC packaging, and other technologies provide the answer. Products such as Samtec’s Si-Fly 112 Gbps PAM4 Low-Profile High-Density Cable System (see Figure 3) connect high-speed signals directly to the silicon package. This eliminates signal distortion by eluding the BGA and routing the signal from the IC package through long reach cable. Combined with an ultra-high-density design, this product enables an aggregate data rate of 25.6 TB with a path to 51.2 TB.

Fig. 3 Products such as the Si-Fly from Samtec offer direct connection to the IC package.

What about performance? When measured at 112 Gbps PAM4 with IEEE 802.3ck allowable loss, the copper twinax Si-Fly demonstrates a 22-inch reach compared to the 4.5-inch reach of MEGTRON7 PCB. The system has been designed to support optical connectivity in the future.

Direct connect to the package offers a path to 224 Gbps PAM4 performance. With reduced loss, tradeoffs can be made on reach or performance. Convergence is the key to 224 Gbps PAM4 system design, and 224 Gbps PAM4 capable solutions are just a silicon design away.

Article was published in the SIJ July 2020 Print Issue, Reflections: Page 14.