Shielding effectiveness is the ability of a cable assembly to either reject interference from the surrounding environment or to prevent the signal in the cable assembly from ‘leaking’ into the surrounding environment and causing interference to other nearby systems or subsystems. While there have been a number of measurement techniques and standards established over the years for the individual components of a cable assembly (i.e., cable and connectors),1-3 it is desirable to know the shielding effectiveness of the entire cable assembly so the designer can have confidence that overall system performance will not be compromised.

Figure 1 Internal view of reverberation chamber.

The mode-stirred method is invaluable in establishing the shielding effectiveness of an entire cable assembly. This is performed in accordance with IEC International Standard 61000-4-214 and detailed in Annex F of this standard.5 The most significant aspect of performing the shielding effectiveness test to IEC 61000-4-21, Annex F is the use of a reverberation chamber (as opposed to an anechoic chamber). An advantage to using a reverberation chamber is stated in IEC 61000-4-21 and is cited here: “Realistic environments for propagation of electromagnetic waves are often characterized by multiple reflections and multipath effects. Reverberation chambers go some way to simulate such complex environments in an extreme manner (worst-case effect) and may be more representative than other EMC test methods in this respect. An advantage of reverberation chambers is the ability to generate a statistically, isotropic, homogeneous, unpolarized and uncorrelated interior field, through the action of the tuner/stirrer.”4

For this reason, Micro-Coax has installed and operates a mode-stir test facility at its factory in Pottstown, Pa. This facility enables real time characterization of shielding effectiveness on microwave cable assemblies from 1 to 18 GHz.

The broad frequency range for this testing dictates the physical size of the chamber since a particular number of ‘modes’ must be present at all frequency points within the chamber to have a statistically uniform RF field within the test volume. As such, a physically larger chamber than might otherwise be expected is required to accommodate lower frequency measurements. A mode stirrer (or tuner) in the chamber then ensures that the internal EM field boundaries of the chamber are constantly changing in order to prevent standing waves. During the measurement cycle, the mode stirrer rotates at a slow uniform rate. The dimensions of the mode stirrer must provide changing boundary conditions across the chamber’s useable frequency range.

An internal view of a typical reverberation chamber showing the mode stirrer (bent structure at top of picture), transmit antenna (red double-ridged horn antenna) and cable assembly under test on the EM field transparent table is shown in Figure 1. The chamber’s internal dimensions are 4.83 × 3.61 × 3.05 m with a lower useable frequency of 200 MHz.6 Ancillary equipment used to generate the RF field within the chamber can restrict the useable frequency range from 1 to 18 GHz.

SETUP

During initial chamber calibration, it is important to determine the location of the ‘working volume’ within the chamber. This is where the E-field of the RF signal is uniform within 3 dB regardless of the direction from which the RF field enters the working volume. This is verified by a series of measurements using directional E-field probes at each corner as well as the center of the working volume (9 locations in all). At each of these locations, individual measurements are made with the directional E-field probes oriented in the ‘X’, ‘Y’ and ‘Z’ directions. This assures that any device under test placed within the working volume is uniformly illuminated by the RF field from every direction. Once uniformity of the E-field is verified, technicians lock down the position of the transmit antenna within the chamber so that the generated fields within the working volume are always uniform.

Using this equipment (see the Associated Equipment Requirements section of this article), typical average E-field values present in the chamber during testing are between 75 and 100 volts/meter in the 1 to 4 GHz frequency range. The average E-field from 4 to 18 GHz falls off linearly from roughly 90 volts/meter at 4 GHz to about 58 volts/meter at 18 GHz. This follows the expected chamber loss documented by the manufacturer and is thus deemed typical for a chamber of that size.

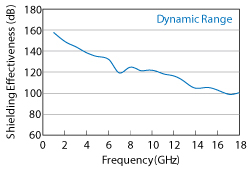

Figure 2 Dynamic range of reverberation chamber.

CALIBRATION AND VERIFICATION

The periodic calibration performed consists of two major steps. The first is to make a measurement of the strength of the RF field within the chamber. This is done by using a receive antenna as the DUT. The receive antenna is the same make and model as the transmit antenna so it exhibits the same gain characteristics. The receive antenna is placed at several random positions within the working volume and at various orientations to provide unbiased measurements. Averaged together, these measurements create the overall chamber ‘baseline’.

The second step is known as the ‘leakage’ measurement. Here the DUT is a well-shielded load. The purpose of the leakage measurement is to determine the minimum signal which can be detected within the chamber. The transmit antenna delivers the same power level to the chamber as during the baseline measurement and the resultant detected signal level shows any flaws in the interconnect cabling present in the chamber as part of the test setup.

The dynamic range of the chamber is the difference between the ‘baseline’ and ‘leakage’ values. One can think of this dynamic range as being the chamber’s ‘noise floor’. The dynamic range is typically greatest at the lower frequencies and decreases as the RF frequency increases. Micro-Coax normally achieves no less than 100 dB dynamic range across the entire 1 to 18 GHz frequency range. When a cable specification calls for 90 dB of RF shielding, the 100 dB dynamic range allows a 10 dB margin in the measurement range. This is a typical margin recommended by various industry specifications. A plot of the chamber’s dynamic range is shown in Figure 2.

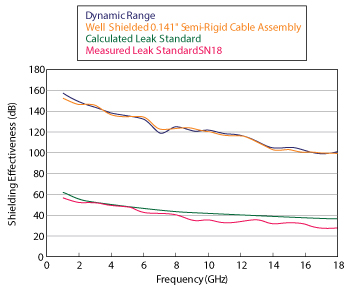

To verify the periodic calibration, two gold standards are employed. One is a cable assembly fabricated from 0.141" diameter semi-rigid cable. This cable has a solid copper outer conductor and uses well-shielded fully soldered SMA connectors. This standard is used to represent a fully shielded cable assembly. From a practical perspective, nothing is fully shielded, but when RF shielding measurements are performed on this device, the resulting measurements are expected to track the dynamic range curve shown in Figure 3. Note that it has been questioned on occasion as to why this standard gives results that are sometimes better than the dynamic curve. The dynamic range is also close to the noise floor of the measurement equipment and the randomness of noise within the equipment can often give these types of readings. This is one reason why the dynamic range of the chamber must be at least 10 dB better than the expected RF shielding measurement.

Figure 3 Gold standards measurements.

The second gold standard is known as a ‘leak standard’7 designed to provide a known amount of RF shielding. The leak standard is patterned after that described in IEC-61726, Annex C and is similar in construction to the fully shielded standard but with a single 0.1" diameter hole drilled in its outer conductor at approximately the midpoint of the assembly. The equations in this IEC specification and the actual RF shielding measurements made with a ‘leak standard’ have been validated to correlate nearly identically to the results shown in Figure 3.

Use of both the well shielded cable assembly and the leak standard cable assembly provides a high degree of confidence in the accuracy of shielding measurements made on cable assemblies, since these assemblies normally fall between the RF shielding values of the two gold standards.

The actual value for RF shielding of a cable assembly is then the difference between the measured RF signal of the cable assembly when placed in the working volume of the chamber and the ‘baseline’ value obtained during the periodic calibration.

Note that verification of the measurement of the leak standard as well as sample cable assemblies has been performed in similar (but not identical) reverberation chambers at test laboratories in the United States as well as in Europe. The close correlation of these independent measurements indicate that the mode-stirred reverberation chamber method of performing shielding effectiveness provides consistent and valid data.

ASSOCIATED EQUIPMENT REQUIREMENTS

The entire RF shielding test is controlled by a proprietary software program developed specifically for this purpose. The signal fed into the chamber is produced by a microwave signal generator driving a switchable power amplifier. The output of the amplifier feeds a securely mounted double ridged horn antenna. RF energy coupled into the DUT is then fed out of the chamber to a spectrum analyzer and converted by the software program into tabular and graphical reports. The internal reference oscillators of the signal generator and the spectrum analyzer are frequency locked.

The spectrum analyzer is set to zero span mode with a very narrow bandwidth. In this configuration, it is essentially a single frequency receiver locked to the same frequency as the signal generator, and displays the signal strength as a function of time. The mode stirrer in the chamber is set to a rotational speed such that in a single sweep on the spectrum analyzer (7 seconds), it will rotate approximately 11/2 times. The signal detected by the spectrum analyzer has peaks and valleys and the software program commands the spectrum analyzer to place and read a marker at the peak of the response for each measured frequency.

EXTENDED CAPABILITY

A physically smaller mode-stirred chamber is used to perform shielding measurements from 18 to 40 GHz. This chamber measures 0.4 × 0.5 × 1.1 m. Pre-measurement calibrations are the same as described for the larger 1 to 18 GHz chamber. Dynamic range is at least 100 dB across the entire 18 to 40 GHz frequency range. Chamber performance is verified by using both the well shielded 0.141" diameter semi-rigid cable assembly as well as the known leak standard.

PRACTICAL MEASUREMENTS

In order to obtain accurate and meaningful shielding effectiveness measurements of a cable assembly, certain practices must be observed. The first is to ensure that the cable assembly is positioned correctly within the working volume of the chamber. No part of the assembly should be allowed outside the working volume as the EM field values have not been measured and verified during chamber calibration and will not fall within the established statistically uniform EM field limits.

Next, it is critical that the connectors on the cable assembly under test be properly mated to the interconnect leads within the chamber. For threaded type connectors, this involves making sure that the proper torque specifications are observed. For push-on and blind-mate connectors, it is necessary that the correct force be used to hold the mating connectors together. If adapters are required, they may be sources of unintended signal leakage and must be validated. Wrapping connections and/or adapter bodies with some form of shielding material may also be required to reduce or eliminate leakage. Typical materials for shielding include bronze and copper wool and copper tape. It is important that any additional shielding material be properly grounded to the cable assembly, otherwise it may become an additional receptor of the EM field surrounding the cable under test and allow extraneous EM energy to be coupled to the inside of the cable assembly.

If the shielding effectiveness measurements appear to be uncharacteristically poor, and all connectors are properly torqued and shielded, any solder joints between the connectors and cable may be suspect. A cable assembly which measures electrically good in terms of insertion loss and VSWR as measured on a network analyzer may still have small voids in the connector to cable solder joint which can allow EM fields at certain frequencies to pass through with little or no attenuation.

Once connectors and solder joints have been validated, the next source of leakage may be the cable itself. A poorly constructed coaxial cable with minimal braid coverage cannot be expected to yield high values of shielding effectiveness. A damaged cable may also leak.

Troubleshooting these types of failures is normally accomplished by trial and error. One approach is to shield various sections of the assembly until the leak is found. Another is to employ methods such as real time X-ray. At the measurement stage, there is little that can be done to correct the effects of using a damaged cable and typically requires replacement. If replacement is impossible, additional shielding may be added over the entire cable in the form of an external braid or sock. This will add weight and cost to the cable assembly, and unless the additional braid is grounded properly to the rest of the cable assembly, could actually cause the shielding effectiveness to deteriorate.

CONCLUSION

RF shielding measurements have been found to be an effective tool in helping to determine the quality and more importantly, the long term reliability of microwave cable assemblies. The mode-stirred method is invaluable in establishing the shielding effectiveness of an entire cable assembly and can be performed in accordance with IEC International Standard 61000-4-21.

References

- Military Standards, MIL-STD-1344A (Method 3008), MIL-STD-461F (RS 103).

- Military Specifications, MIL-PRF-39012, MIL-C-85485.

- Industry and International Standards, EIA-364-66A, IEC 60096-1.

- IEC International Standard 61000-4-21:2011, “Testing and Measurement Techniques – Reverberation Chamber Test Methods.”

- IEC International Standard 61000-4-21:2011 Annex F, “Shielding Effectiveness Measurements of Cable Assemblies, Cables, Connectors, Waveguides and Passive Microwave Components.”

- ETS-Lindgren SMARTTM200 Chamber, www.ets-lindgren.com/SMART200

- IEC International Standard 61726:2001 Annex C, “Example of a Calibrator.”