What if the characteristic impedance of the transmission line is significantly different from the termination impedance? Let’s take a look at a 25 Ω stripline in the same stackup as before, shown in Figure 3.

Magnitudes of the transmission (insertion loss) and reflection in dB are shown on the top plot and TDR on the bottom. The reflection went up considerably, that means more signal energy is reflected. As the result, the transmission or insertion losses went down at some frequencies — less signal energy is transmitted. The insertion loss now is wavy and repeats the reflection pattern — maxima in the reflection are the minima in the insertion losses. The signal energy here is either reflected or absorbed. The top plot also has the expression for the reflection parameter — the hyperbolic tangent in the denominator explains the minima and maxima—it is trigonometry, though with the complex numbers. S-parameters are used directly to compute the TDR that shows some multiple reflections from the ends of the segment in this case.

Another case with considerably larger characteristic impedance about 75 Ω (cannot be exact) and same segment length and 50 Ω terminations is shown in Figure 4. The S-parameter plot looks very similar to the previous 25 Ω case. Though, it has more conductive losses and the TDR goes up, instead of down, and shows more resistance (slope up) in the narrow transmission line as expected. In both “reflective” cases only one or two reflections are significant – it disappears quickly due to the absorption losses (losses are our friend in such reflective cases).

Optimal Characteristic Impedance

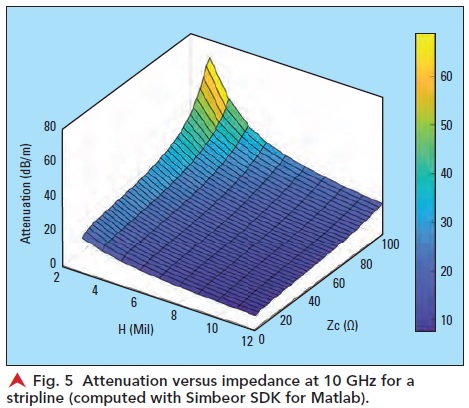

of an air-filled coaxial transmission line between the maximal transmitted power and minimal losses.7 Indeed, a coaxial line always has a minimum in losses vs. impedance. Though it is dependent on the dielectric fill, but it happens to be close to 50 Ω for coaxial lines filled with PFTE-type dielectric with Dk close to 2.7 As we know, striplines are the descendants of the coaxial transmission lines, but the stripline losses do not have minimum on the loss versus impedance function. Here is the attenuation in dB/m for a stripline modeled with Dk=3.5, LT = 0.002 at 1.0e9, Huray-Braken roughness model: SR = 0.1 μm, RF = 9 as a function of dielectric thickness and characteristic impedance at 10 GHz, shown in Figure 5.

The attenuation is lower for the lower characteristic impedance (Zc axis) as well as for the thicker dielectrics (H axis). The conductor losses dominate in striplines with very low loss dielectrics.2 It means that the crosssections with more metal and lower impedance have smaller losses in general. Though, the single mode propagation condition and layout density may put additional bounds on the increase of the cross-section size and on the lowest impedance as well. So, is the lower impedance always better? Not really, if our goal is to minimize the power absorbed by the interconnects and terminators. For instance, if we need 0.1 V signal at the receiver and compute power required at the transmitter side (Pin=20log(Vout)-10log(|Zc|)+Att_dB*Length, dBW), we will see some minima (same example as above at 10 GHz) as shown in Figure 6.

The minimal power depends on the geometry (dielectric thickness H above and below trace and trace width adjusted to have an impedance value on the x-axis) and also on length (plots are for a 1 m segment). Lower impedance should be considered for thinner dielectric layers. Strip widths in this example are set to have the impedance shown on the x-axis (Simbeor SDK used for computations). Terminations in this case were set equal GHz (no reflections). As we can see, the lower characteristic impedance is not always better and may be optimized for a particular system.

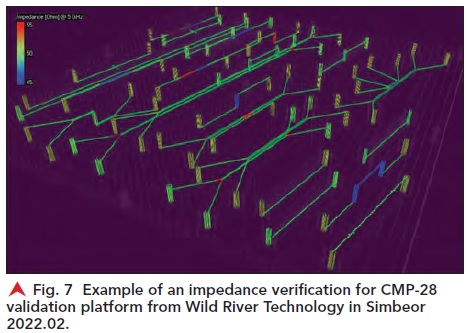

The green color is used for objects with the impedance close to the target impedance (50 Ω

single-ended or 100 Ω

differential). Objects with the impedance below the target are blue and with higher impedances are red. This is a well designed board with a small number of intentional impedance violations in some structures. Also, it comes from Wild River Technology with the measurements up to 50 GHz for validation purposes. Simbeor evaluates the input impedance of the vias with fast EM models of multi-vias (signal + stitching vias) and impedance of traces with Simbeor SFS 2D field solver at the Nyquist frequency.

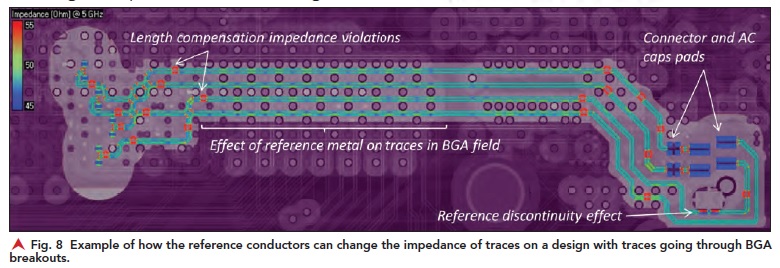

Another example of how the reference conductors can change the impedance of traces on a design with traces going through BGA breakouts is shown in Figure 8. Here Simbeor evaluated effect of the cut-outs and reference pads on the impedance—those cannot be avoided. We can see that the impedance of connector and AC coupling pads is below the target and the impedance of the length compensation sections are above the target (layout mistake). The discontinuities in the reference conductors also create impedance violations (another layout mistake). Though, most of those violations may not kill the signal and are important at relatively high data rates.

7. “Why Fifty Ohms?,” Microwaves 101, Web: https://www.microwaves101.com/encyclopedias/why-fi fty-ohms.